PRODUCT FEATURES

Concrete Pump Machine Manufacturer to Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is pilotruck.com

Pilotruck.com have seen that today there are also many heavy truck companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and pilotruck.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

A Definitive Guide To Concrete Pump Machine

Concrete pump machines are a staple in the construction industry. Chances are, if you’re involved in a construction project, you’ll need to use one at some point. But what do you need to know about these machines before you buy one?

A concrete pump machine is a type of equipment that is used to transfer liquid concrete from one place to another. It is usually composed of a pumping system, a hose, and a delivery pipe. When it comes to buying a concrete pump machine, there are many factors that you need to consider.

In this article, we will discuss what concrete pump machines are, how they work, and why they are becoming more popular amongst businesses. We will also outline some tips for choosing the right concrete pump machine for your needs. So, let’s get started!

Table of contents

1. An Overview About Concrete Pump Machine

A concrete pump is a machine used for transferring liquid concrete by pumping. It is often used in construction projects, such as buildings and bridges. Concrete pumps can be powered by either electric motor or diesel engines.

Concrete pump machine work by using a system of pistonsto transfer concrete from the hopper to the delivery hose. The concrete is then pumped through the hose to the desired location.

Concrete pump machines are available in a variety of sizes, from the small portable concrete pump to large, stationary units. They can also be fitted with a variety of accessories, such as concrete mixers and concrete vibrators.

2. 3 Most Common Uses of Concrete Pump Machine

Concrete pump machines are commonly used in a variety of construction projects. Some of the most common uses for concrete pump machines include:

#1 Foundation Work

Concrete pump machines are often used to pour concrete foundations for both homes and commercial buildings. The concrete pump machine is able to pump concrete into difficult-to-reach places, making it ideal for foundation work.

#2 Pouring Concrete Slabs

Concrete pump machines are also commonly used to pour concrete slabs. This includes concrete slabs for driveways, patios, and sidewalks. The concrete pump machine is able to pour concrete evenly, which results in a professional finish.

#3 Filling Gaps and Holes

A pump for concrete machines can also be used to fill in gaps and holes. This includes filling in cracks in concrete walls or concrete floors. The concrete pump machine is ideal for this type of work because it can precisely control the amount of concrete that is dispensed.

As you can see, diesel concrete pump machines are versatile and can be used for a variety of different projects. If you have a construction project that requires concrete, a concrete pump machine may be the ideal solution.

3. 4 Main Types of Concrete Pump Machine

There are different types of concrete transfer pump machines available in the market that are designed for specific needs and requirements. Depending on the construction project, different types of concrete pumps can be used.

Here are some of the main types of concrete pump machines that are commonly used:

#1 Boom Concrete Pumps

These are concrete pumps that come with a boom or an arm that can be raised and lowered. The boom concrete pump is ideal for projects where concrete needs to be poured at a high height or in a difficult-to-reach area.

#2 Stationary Concrete Pumps

These are concrete pumps that are mounted on a stationary platform, making them ideal for projects where concrete needs to be poured into a specific area.

#3 Trailer Concrete Pumps

These concrete pumps are mounted on a trailer, making them easy to transport from one location to another. Trailer concrete pumps are ideal for construction projects that require concrete to be poured in multiple locations.

#4 Line Concrete Pumps

These concrete line pumps are designed to pump concrete through a long pipeline, making them ideal for projects where concrete needs to be poured over a long distance or in a difficult-to-reach area.

These are some of the main types of concrete machine pumps that are available in the market. Depending on the construction project, different types of concrete pumps can be used. Choose the concrete pump machine that is best suited for your needs and requirements.

4. The Benefits of Investing in a Concrete Pump Machine

If you’re in the construction business, then you know that concrete is one of the most important materials used in building and infrastructure projects. And if you’re looking for a way to increase your productivity and efficiency, then investing in a concrete pump machine is a great option.

Here are just some of the benefits of investing in a concrete pump machine:

Increased Productivity and Efficiency

Concrete pump machines can greatly increase your productivity and efficiency. With a concrete pump machine, you can easily and quickly move concrete from one place to another, which means that you can get the job done faster and with less effort.

Reduced Labor Costs

Concrete pump machines can help reduce your labor costs. With a concrete pump machine, you can move concrete without the need for manual labor, which can help save you money on your labor costs.

Increased Safety

Concrete pump machines can also help improve safety on the job site. With a concrete pump machine, you can avoid the dangers of manual concrete handling, which can help reduce the risk of injury on the job site.

These are just some of the benefits of investing in a concrete pumping machine. With all of these benefits, it’s easy to see why concrete pump machines are a great investment for any construction business.

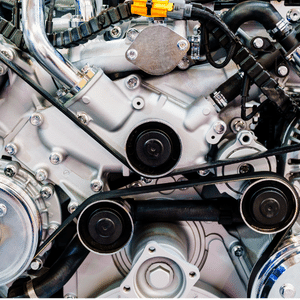

5. Concrete Pump Machine: Manufacturing Process

The manufacturing process of concrete pump machines is a complex and intricate process that involves many different steps. Here is a brief overview of the concrete pump machine manufacturing process:

| No. | Steps |

|---|---|

| 1 | Assembling the frame |

| 2 | Installing the Axles and Suspensions |

| 3 | Finishing the Frame |

| 4 | Painting the Chassis |

| 5 | Installing the Engine and Transmission |

| 6 | Finishing the Chassis |

| 7 | Assembling the Cab, Hood, and Sleeper |

| 8 | Painting the Cab, Hood, and Sleeper |

| 9 | Finishing the Cab, Hood, and Sleeper |

| 10 | Installing the Cab, Hood, and Sleeper |

| 11 | Adding Fluids |

| 12 | Aligning the Front and Rear Axles |

| 13 | Testing the Completed Truck |

Step#1 Assembling the frame

The first step in the concrete pump machine manufacturing process is assembling the frame. This is done by welding together the side members, end members, and cross members.

Step#2 Installing the Axles and Suspensions

The next step is to install the axles and suspensions. This is done by attaching the axle brackets to the frame and then attaching the suspension members to the axle brackets.

Step#3 Finishing the Frame

The next step is to finish the frame. This involves adding the bracing members and the support members.

Step#4 Painting the Chassis

The next step is to paint the chassis. This is done to protect the concrete pump machine from corrosion and to give it a professional finish.

Step#5 Installing the Engine and Transmission

The next step is to install the engine and transmission. This is a critical step in the manufacturing process of concrete pump machines, as the engine and transmission must be properly aligned in order for the machine to function correctly.

Step#6 Finishing the Chassis

The next step is to finish the chassis. This involves adding wheels, tires, and other accessories.

Step#7 Assembling the Cab, Hood, and Sleeper

The next step is to assemble the cab, hood, and sleeper. This is done by attaching the cab to the frame, attaching the hood to the cab, and attaching the sleeper to the frame.

Step#8 Painting the Cab, Hood, and Sleeper

The next step is to paint the cab, hood, and sleeper. This is done to protect the concrete pump machine from corrosion and to give it a professional finish.

Step#9 Finishing the Cab, Hood, and Sleeper

The next step is to finish the cab, hood, and sleeper. This involves adding the windows, doors, and other accessories.

Step#10 Installing the Cab, Hood, and Sleeper

The next step in the process is to install the cab, hood, and sleeper. This is done by attaching the three parts to the main body of the concrete pump machine. The cab is the most important part of the machine, as it houses the controls that operate the concrete pump.

The hood protects the engine from weather and debris, and the sleeper provides a comfortable place for the operator to rest while the concrete pump is in operation.

Step#11 Adding Fluids

The next step is to add fluids. This includes adding oil to the engine, coolant to the radiator, and hydraulic fluid to the concrete pump.

Step#12 Aligning the Front and Rear Axles

The next step is to align the front and rear axles of the concrete pump machine. This is done by first attaching the axle to the frame, and then lining up the axle with the concrete pump’s body. Once the axle is aligned, it is bolted into place.

Step#13 Testing the Completed Truck

The final step in the concrete pump machine manufacturing process is testing the completed truck. This is done to ensure that the concrete pump machine is safe and ready to use.

After the concrete pump machine passes all of the tests, it is ready to be sold to the customer.

These are the steps involved in the concrete pump machine manufacturing process. The process is complex and requires a great deal of precision and skill. However, when the process is completed, the result is a concrete pump machine that is safe and ready to use.

To learn more about how a Concrete Pump Machine works, take a look a t this video.

6. The Average Cost of Concrete Pump Machine

The cost of concrete pump machine concrete depends on several factors, including the location, size, and type of concrete pump machine you concrete. However, the average concrete pump machine concrete costs between $3,500 and $4,500.

When shopping for a concrete mixer with pump for sale, be sure to ask for quotes from multiple concrete pump machine concrete providers to get the best price. Also, be sure to ask about any discounts or promotions that may be available.

Some discounts may be available for large concrete pump machine concrete purchases, or for concrete pump machine concrete that is purchased in bulk. Be sure to compare the prices of different providers to get the best deal possible.

7. Where To Find Concrete Pump Machine Manufacturers

If you’re in the market for a concrete pump machine, you’ll want to find a reputable manufacturer. There are many concrete pump machine manufacturers out there, but not all of them are created equal.

Here are some places to look for concrete pump machine manufacturers:

Online Directories

Online directories are a great place to start your search for concrete pump machine manufacturers. You can find many different manufacturers listed in these directories, which will give you a good idea of who is out there and what they offer.

Trade Shows

Attending trade shows is a great way to see concrete pump machines in person and to talk to manufacturers directly. This can be a great way to get a feel for a manufacturer before making a purchase.

Word of Mouth

As with anything, word of mouth can be a great way to find concrete pump machine manufacturers. Talk to people you know who have purchased concrete pump machines in the past and see if they have any recommendations.

Manufacture’s Website

If you have a concrete pump machine manufacturer in mind, be sure to visit their website. This is a great way to learn more about the company and what they offer. You can also usually find contact information on the website, which you can use to get in touch with the manufacturer directly.

These are just a few of the many places you can look to find concrete pump machine manufacturers. By doing your research, you can be sure to find a reputable manufacturer that offers the products you need.

If you’re looking for a reputable manufacturer of concrete pump machines, Pilotruck is a great option. We offer a wide variety of concrete pump machines, as well as other concrete pumping equipment.

We’re also happy to answer any questions you may have about our products. Contact us today to learn more about our products and services.

8. Concrete Pump Machine: Care and Maintenance

As with any machinery, concrete pump machines require regular care and maintenance to keep them functioning properly. Fortunately, concrete pump machine care and maintenance are not difficult or time-consuming, as long as it is performed regularly.

Here are the concrete pump machine care and maintenance tips:

Lubricate the Moving Parts

One of the most important aspects of concrete pump machine care and maintenance is keeping the moving parts lubricated. This will help to prevent wear and tear on the machine, as well as reduce noise levels.

To lubricate the moving parts, you will need to use a high-quality lubricant that is designed for use on concrete pump machines. Apply the lubricant to all of the moving parts, including the piston, cylinder, and bearings.

Inspect the Machine Regularly

Another important aspect of concrete pump machine care and maintenance is performing regular inspections. These inspections should be done at least once a week, and more often if the machine is being used frequently.

During your inspection, you will want to check for any signs of wear or damage. If you notice any problems, make sure to repair or replace the damaged parts as soon as possible.

Keep the Machine Clean

It is also important to keep the concrete pump machine clean. This can be done by using a pressure washer to remove any dirt or debris that has accumulated on the machine.

Make sure to avoid using too much pressure, as this could damage the machine. Once you have cleaned the concrete pump machine, dry it off with a clean cloth to prevent rusting.

Store the Machine Properly

When you are not using the concrete pump machine, it is important to store it properly. This will help to prevent damage and keep the machine in good condition. The concrete pump machine should be stored in a dry, sheltered area that is out of direct sunlight.

If possible, cover the machine with a tarp or other type of protective cover to keep it clean and dry.

These are just a few concrete pump machine care and maintenance tips that you should follow to keep your machine in good working condition. By taking the time to properly care for your concrete pump machine, you can extend its lifespan and ensure that it will continue to work properly for years to come.

9. 5 Buying Tips About Concrete Pump Machine You Can’t Afford to Miss

When it comes to concrete pump machines, there are a few key factors that you need to keep in mind before making your purchase. Here are some tips that will help you choose the right concrete pump machine for your needs:

#1 Quality

The first and most important factor to consider when choosing a concrete pump machine is quality. You want to make sure that you buy a machine that is built to last and can withstand the rigors of any job site.

There are many different brands and models of concrete pump machines on the market, so it is important to do your research to find the one that best suits your needs.

#2 Size

The next factor to consider is the size of the concrete pump machine. You need to make sure that you choose a machine that is able to handle the volume of concrete that you will be using.

#3 Power Source

Another important factor to consider is the power source of the concrete pump machine. There are machines that are powered by electric motors and others that are powered by gas engines.

You need to choose a machine that is compatible with the power source that you have available so that you can avoid any issues.

#4 Price

Of course, you also need to consider the price when selecting a concrete pump machine. There are many different models and brands available, so you should be able to find one that fits your budget.

#5 Warranty

Finally, you should also make sure that you buy a concrete pump machine that comes with a warranty. This will give you peace of mind in knowing that you are covered in case anything goes wrong with the machine.

By following these tips, you should be able to find the perfect concrete mixer machine with pump for your needs. Be sure to do your research and compare different models before making your final decision.

If you’re looking for a concrete pump machine for sale, you can check out our website at Pilotruck. We offer a wide variety of concrete pump machines at competitive prices. Visit us today to learn more!

10. Conclusion

In order to stay ahead of the competition and ensure that your concrete pumping business is running as efficiently as possible, it’s important to be aware of the latest advancements in this industry.

That’s why we’ve put together a comprehensive guide on concrete pump machines – so you can stay up-to-date on all the latest trends and technologies. If you have any questions about how concrete pumps can benefit your business, don’t hesitate to contact us at Pilotruck. We would be happy to help!

FEATURE BLOGS

READY TO LEARN MORE?

Unsure of which dump truck is right for your business? This comprehensive guide will help make the process easier!

Are you looking to buy a new concrete truck? This guide will help you get the highest value for your money.

Looking to learn all there is to know about concrete pumps? Here’s everything you need to know, including how they work, the different types of concrete pumps, and what makes them a great choice for any project.